Full Video of the Central Heating Controller System

How Do Central Heating Controllers Work?

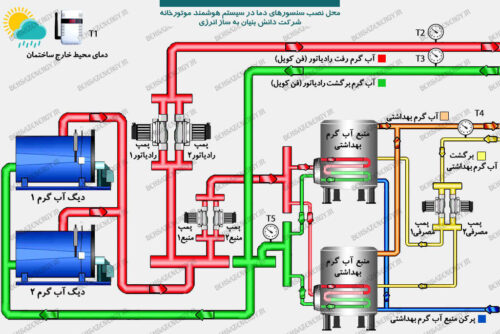

A Central Heating Controller operates using four temperature sensors installed in the Central Heating Engine Room and one outdoor temperature sensor. It continuously monitors outdoor temperature and internal conditions, performing real-time calculations to adjust thermostat settings on boilers and circulation pumps. By turning burners and pumps on or off as needed, the system ensures the hot water supply aligns with the building’s current needs. This approach not only meets heating demands but also prevents energy waste by tailoring heat production to the building’s requirements.

Energy Optimization for Non-Residential Buildings

In non-residential buildings—such as offices, commercial spaces, schools, or villas—that are often unoccupied during nights or non-working hours, traditional Central Heating Engine Rooms operate unnecessarily. Central Heating Controllers with programmable schedules are an ideal solution to address this inefficiency.

These systems allow operating hours to be defined for each day. For example, the system can shut down the Central Heating Engine Room after work hours and reactivate it a few hours before the building reopens, ensuring it is warm and ready for use. If outdoor temperatures drop to levels that risk freezing pipes, the system switches to a standby mode to prevent damage, balancing energy efficiency with infrastructure protection.

Installation and Setup of Central Heating Controllers

Behsaz Energy, a leader in energy optimization, offers high-quality installation and commissioning of Central Heating Controllers in minimal time. The process involves two main phases:

- Central Unit Installation

The central unit integrates into the electrical circuit of the Central Heating Engine Room, including:

- Burners

- Circulation pumps for radiators or fan coils

- Domestic hot water circulation pumps

The central unit outputs connect in series with equipment electrical circuits, enabling on/off commands to contactors or relays for burners and pumps. Mechanical thermostats on the equipment are set to 85°C to serve as backup safety mechanisms in emergencies.

- Sensor Installation

Four digital temperature sensors connect to the central unit via cables and are installed as follows:

- On pipe surfaces under insulation: These sensors measure equipment temperature with high accuracy.

Outdoor temperature sensor: Mounted on the building’s north-facing wall. When cabling to the central unit is impractical, the sensor connects wirelessly via a transmitter-receiver module, avoiding wall demolition or additional cabling

Examples of Central Heating Controller Projects by Behsaz Energy

Advantages of Central Heating Controllers

Central Heating Controllers are easy to install, even in occupied and operational buildings, without significant disruption. Key advantages include:

- No Demolition or Welding Needed

Installation requires no cutting, water drainage, or structural damage to the building. - Quick Installation Time

The process is completed within hours, with Central Heating Engine Room downtime lasting less than an hour. - Year-Round Installation

The system can be installed in any season or condition without timing constraints.

Using advanced technology and a simple installation process, the Central Heating Controller from Behsaz Energy enhances efficiency, reduces energy consumption, and prolongs equipment lifespan.

How It Works

The Central Heating Controller optimizes performance through:

- Real-Time Temperature Control

- Adjusts boiler water temperature (used in radiators, fan coils, etc.) by controlling burner and circulation pump operations.

- Ensures stable indoor temperatures, improves thermal comfort, and reduces equipment wear and tear.

- Maintaining Domestic Hot Water Temperature

- Prevents a drop in hot water temperature, especially during peak usage.

- Regulates boiler operations to maintain hot water supply without excessive indoor heating.

- Scheduled Operation for Part-Time Buildings

- Schedules Central Heating Engine Room operations to shut down or remain on standby during non-working hours, enhancing energy efficiency.

- Real-Time Temperature Control

Fuel Savings

- Residential Buildings

- Optimizing operations reduces fuel consumption by about 15%, translating to 25–30% savings on gas bills under tiered pricing.

- Non-Residential Buildings

- Scheduled off-hours for the boiler system save 35–45% on fuel, with even greater reductions in gas bills due to lower usage.

For effective energy management and cost savings, Central Heating Controllers deliver unmatched efficiency and convenience.

- Residential Buildings

FAQ

Technical Specifications of the Central Heating Controller System

| عنوان | توضیحات / Description | Title |

|---|---|---|

| وزن خالص دستگاه | 884gr | Net Weight |

| قابلیت عملکرد دستگاه در رطوبت محیط | 85% | Operating Relative Humidity |

| قابلیت عملکرد دستگاه در دمای محیط | Temp. - 20 ~ + 50 ºC | Operating temperature |

| نوع خروجی های دیجیتال / اتصال | Rellay (16 Amp) / Phoenix | Digital output system |

| تعداد خروجی های دیجیتال | 8Pcs | No. of DO (Digital output) |

| توان خروجی های دیجیتال | Max 5-6 Amp | Digital output current |

| نوع سنسور های دما و دقت اندازه گیریx` | Digital (0.01 ºC resolution) | Thermal Sensors Type (Sensivity) |

| نوع اتصال سنسورهای دما | Wire (RJ45) - Wireless (RF) | Type of thermal sensor connection |

| بسترهای ارتباطی | RF (915 Mhz) / LAN (INTERNET ETHERNET) / GPRS | Communications system |

| پروتکل های قابل پشتیبانی در شبکه اینترنت و اترنت | TCP,UDP,ICMP,IPV4 ARP,IGMP, PPPOE,ETHERNET AND SUPPORT ADSL, CONNECTION WITH SUPPORT PPPOE PROTOCOL WITH PAP/CHAP | SUPPORTED PROTOCOLS (Internet and Ethernet) |

| ساختار شبکه | Web Server – Web Service | Network protocol |

| نوع نمایشگر | Dot Matrix 128*64 | Display |

| حافظه جانبی | USB (Flash Memory) | Data Logger |

| ساخته شده | Behsaz Energy (Iran) | Made By |

Reviews

There are no reviews yet.